What Is a Superconducting Wire?

Leave a CommentSince 1977, our company has been producing Oxygen Free High Conductivity Copper (OFHC) components, materials, and stock blanks for an extensive variety of industrial applications. Our USA facility specializes in OFHC rods and wiring, as well as superconducting wire. Superconducting wire offers superior conduction of electricity with minimal inefficiency, making it a popular choice for energy generation and critical applications. Our magnesium diboride (MgB2) wire is a superconducting wire material that also withstands high temperatures.

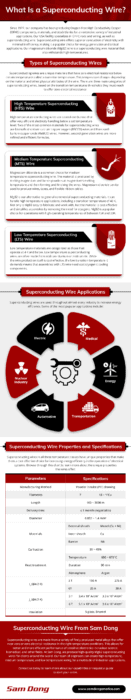

Types of Superconducting Wires

Superconducting wires are unique materials that have zero electrical resistance below certain temperatures called a transition temperature. This temperature changes depending on the material and other physical attributes of the wire. There are three main categories of superconducting wires, based on the transition temperatures thresholds they must reach to offer zero electrical resistance:

High Temperature Superconducting (HTS) Wire

High temperature conducting wires are coated conductors that offer very efficient electricity handling below a set temperature level. Two of the most common materials for superconducting wires are bismuth strontium calcium copper oxygen (BSCCO) wires and Rare earth barium copper oxide (ReBCO) wires. However, second-generation wires are more refined and efficient formulas.

Medium Temperature Superconducting (MTS) Wire

Magnesium diboride is a common choice for medium temperature superconducting wire. The material is produced by melting magnesium and boron powders at magnesium’s melting temperature and then forming and finishing the wires. Magnesium diboride can be used to produce wires, tapes, and flexible ribbon cables.

MgB2 is our alternative to general commercial superconducting materials. It can handle high-temperature applications, including a transition temperature of 40 K. Not only is MgB2 easy to fabricate and work with, but the material is cost-effective and simplifies assemblies by removing the need for cryogens. MgB2 is a popular choice for operations with high operating temperatures of between 15K and 30K.

Low Temperature Superconducting (LTS) Wire

Low temperature materials are categorized as those that operate at 4 K and below. Low temperature superconducting wires are often made from niobium titanium or niobium tin. While the wire production itself is cost-effective, the low transition temperature it demands means that assemblies with LTS wire need cost cryogenic cooling components.

Superconducting Wire Applications

Superconducting wires are used throughout almost every industry to increase energy efficiency. Some of the most popular applications include:

Medical

Magnetic resonance imaging (MRI) and nuclear magnetic resonance (NMR) equipment use superconducting wires. Biomagnetic devices are noninvasive medical technologies that allow medical professionals to observe and diagnose conditions.

Energy

Generator, wind energy turbines, transformers, and more all utilize superconducting wires to more efficiently generate, transport, and distribute energy.

Transportation

Magnetic levitation (Maglev) systems use superconducting wires in the components controlling the electromagnets in the system. This can be used for high-speed train systems, such as the Yamanashi MLX01 MagLev train.

Automotive

Superconducting wires dramatically improve the performance of engines in electric vehicles.

Nuclear Industry

Scientific and nuclear energy production facilities rely on high-quality superconducting wires to handle the power for nuclear fusion systems and particle accelerators. The Large Hadron Collider has superconducting wire.

Electric

Electric devices use superconducting wires, cables, and ribbons. Electric utilities also use superconducting wires in their transformers.

Superconducting Wire Properties and Specifications

Superconducting wires in all three temperature classes have unique properties that make them a cost-effective choice for increasing energy efficiency in the operation of electrical systems. Browse through this chart to learn more about the unique properties the wires offer:

| Parameters | Specifications | ||

| Manufacturing method | Powder in tube (PIT) drawing | ||

| Filaments | 7 | 18 + ‘1’Cu | |

| Length | 100 ~ 3000 m | ||

| Delivery time | ≤ 1 month (negotiable) | ||

| Diameter | 0.832 ~ 1.4 mmø | ||

| Materials | External sheath | Monel (Cu + Ni) | |

| Inner sheath | Cu | ||

| Barrier | Nb | ||

| Cu fraction | 30 ~ 45% | ||

| Heat treatment | Temperature | 650 ~ 675°C | |

| Duration | 30 min | ||

| Atmosphere | Argon | ||

| Ic (@4.2 K) | 3 T | 150 A | 275 A |

| 6 T | 25 A | 30 A | |

| Jc (@4.2 K) | 3 T | 3.4 x 105 A/cm2 | 3.3 x 105 A/cm2 |

| 6 T | 5.1 x 104 A/cm2 | 3.6 x 104 A/cm2 | |

| Insulation | S-glass, Enamel | ||

Superconducting Wire From Sam Dong

Superconducting wires are made from a variety of finely produced metal alloys that offer near-zero or zero electrical resistance in the right temperature conditions. This allows for better and more efficient performance of sensitive electronics in nuclear science, biomedical, and other fields. At Sam Dong, we produce high-quality MgB2 superconducting wires for clients around the world. Our team of engineers can create high temperature, medium temperature, and low temperature wiring for a multitude of industrial applications. Contact us today to learn more about our capabilities or request a quote to start your order.